What Is Hemp Plastic?

Plastic was virtually unheard of before the 1960s. Fast forward just six decades and plastic pollution has become one of the most critical environmental issues we’ve ever faced. Every year, some 8 million tons of plastic finds its way into the ocean. What does 8 billion tons of plastic look like? Picture five garbage bags full of trash on every foot of the world’s coastlines. Experts predict that by 2050, there will be more plastic in the ocean than fish.

As dedicated as you might be to recycling and reducing the plastic you use, we must do more to make a difference in facing the enormity of the plastic crisis. Plastic alternatives are vital to the future of our planet. Hemp plastic is one alternative that some think could be the replacement for petroleum-based plastics our planet so desperately needs.

What Is Hemp Plastic?

Hemp plastic is a type of bioplastic, or plastic material made from biomass material. While corn, sugarcane and sugar beet are the most common materials that are used to make bioplastics, plastic made with hemp could well become the plastic of the future.

The basic foundation of the traditional plastic that has flooded the marketplace is basically a cellulose derived from petroleum. These plastics can also be made from plant cellulose. The inner woody part of the hemp stalk, hemp hurd, happens to be about 80-85% cellulose.

How Is This Plastic Made?

The cellulose found in hemp is the primary ingredient used to make this type of plastic. Once it is extracted from the hemp plant, the cellulose is dissolved in an alkali mixture. From there, it’s put in a sulphuric acid bath, which creates a cellophane film. To create rayon, another type of plastic, the cellophane film is then put through a spinneret. Celluloid is another type of plastic that can be created with hemp.

Hemp Plastic is Stronger than Other Plastics

Not only is hemp plastic sustainable, but it’s also much stronger than petroleum-based plastic or other bioplastics. Hemp fiber is one of the strongest fibers that exist and it has a long history of use as an industrial product. Historically, hemp was used to make ropes and sails for ships.

A 2003 study investigated whether natural fibers could replace glass fiber in reinforced plastics. It found that hemp, sisal and kenaf showed comparable tensile strength (the resistance of a material breaking under tension). Hemp also had the strongest impact properties of all natural fibers tested. Researchers of the study concluded that “natural fiber composites were found to compare favorably with those of glass.”

Different Types of Hemp Plastic

There are various types of this plastic that could pave the way for a cleaner environment in the future.

In Australia, Hemp Plastics is a company that works with partners who have created a material that is 100% biodegradable and made from hemp and corn. This completely natural plastic material can be molded using state-of-the-art technology or injected into any shape using prevailing plastic molds.

Zeoform, also in Australia, created a resin made from this plastic known as Hempstone, made only with water and natural cellulose fibers like you’d find in hemp. According to Zeoform, the proprietary process they use “converts cellulose fibers into an industrial strength molding material capable of being formed into an unlimited array of products.”

Traditional plastics that are infused with hemp fibers are the most common plastics made with hemp. This means that most plastics made from hemp that are currently available are a mixture of petroleum-based plastic and hemp plastic.

This represents a small step away from our reliance on fossil fuels. Infusing plastic with hemp fibers cuts down on the amount of petroleum-based plastic used, which results in less dependence on oil and less pollution. As it now stands, roughly 8% of the entire world’s oil is sourced to produce plastic.

Is Hemp Plastic Better than Other Bioplastics?

Most bioplastic currently available is made from corn. However, a 2010 study found some concern with growing a food crop like corn to produce bioplastics. One issue was the land that was used for plastic production could instead be used to cultivate food. Another was the amount of fertilizer necessary to grow such crops.

Cultivating hemp for plastic could be the solution to concerns such as these.

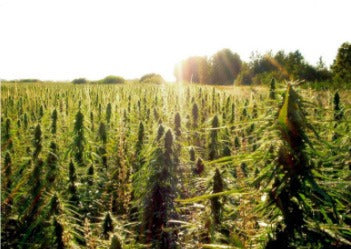

Aside from harsh desert areas and high mountain regions, hemp grows pretty much anywhere. According to the Modern Farmer, hemp also grows more vigorously than corn, and requires less water, pesticides, herbicides and fertilizer.

The Past, Present and Future of This Plastic

Hemp plastic isn’t anything new. In fact, in 1941 Henry Ford built a car that was made almost entirely of this plastic. Not only was it lighter than steel but it could also endure ten times the impact without denting.

Today, several car manufacturers are utilizing hemp to make various automobile parts. BMW, Chrysler, Ford, GM, Honda, Mercedes and Saturn all use hemp to create door panels, dashboards, boot linings, instrument panels and more.

While the hemp plastic industry is still in its early days, there are several companies that already exist and offer products like hemp water bottles, hemp plastic straws, cups and more.

There’s no doubt that the creation of plastic made from hemp and other bioplastics is increasing. According to Canopy Corporation, an American company that provides hemp processing services, “the possibilities are endless with hemp plastics.” They suggest that it’s just a matter of time before this plastic will replace several plastic products including cell phone chargers, cookware, laptops, sockets, toys, construction materials and more.

Can Hemp Plastic Replace Traditional Plastic?

No matter how conscious you are about the plastic you consume, there’s no getting around the fact that plastic has infiltrated essentially every aspect of our lives. What we can do is become more mindful about our plastic consumption.

Picture a world where this bioplastic replaced traditional plastic. Anything’s possible, just take a look at hemp’s recent history. Illegal for almost a century, today it is poised to become the country’s cash crop.

It will be a long and difficult process to replace traditional plastic with hemp plastic. The global market for plastic is huge and is growing at about 3% a year. By 2020, the global market for plastics is estimated to be worth $1.2 trillion and there are huge enterprises that plan to continue to profit from plastic production.

Change, as always, is the only constant. Considering how far we’ve come with hemp in such a short time, hemp plastic could very well become the wave of the plastic future.

Thanks for reading! To show how much we appreciate you, we’re going to give you 16% off your next order. Just use code READER16 at checkout!

Newsletter signup

Join the Joy Organics Family

Sign up and get updates on new products, as well as special coupons and discounts.

testimonials

What Our Clients Say

“This is a company that truly cares about its customers and providing the best CBD products currently available on the market.”

Join In On The Conversation

Your email address will not be published. Required fields are marked *

Comments will be approved before showing up.